The use of 3D software for the planning of an implantology intervention has contributed to further innovation in the field of dentistry.

In particular, compared to previous surgical techniques, the possibility of using technologies such as 3D software and other very high precision instruments has made implant surgery much less invasive and with very high success guarantees.

How do you use 3D software in implantology?

A center specialized in implantology, like Sanident, uses 3D software to design every implantology intervention with maximum precision.

The 3D software comes into play after acquiring the three-dimensional images of the patient’s dental arches. Images can be acquired in different ways:

- Through the Tac Cone Beam 3D Gendex technology

- Through the 3D intraoral scanner

- Through the 3D acquisition of a classic radiological examination

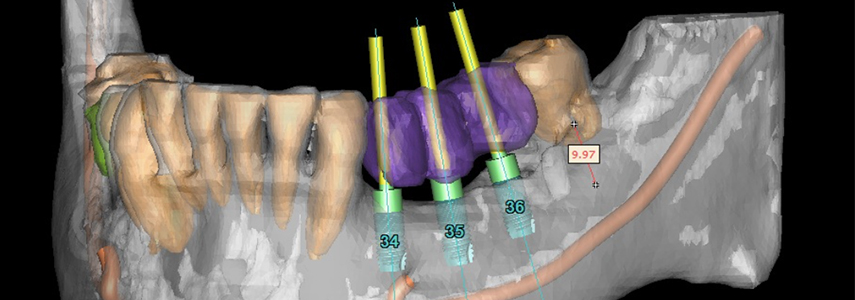

Once the dentist has acquired the information, he will be able to transfer it to the 3D software thanks to which he will be able to plan the intervention in its smallest details.

Once the dentist has acquired the information, he will be able to transfer it to the 3D software thanks to which he will be able to plan the intervention in its smallest details.

The 3D software is able to support the dentist in different stages of the design.

In the first instance, it can facilitate the doctor in simulating the operation with the calculation of bone density, chewing loads and the exact definition of the type of implant with an indication of the exact points where the implants can be inserted, their size and length .

Starting from the simulation data obtained through the 3D software, the dentist will have the opportunity to proceed in the design with different actions.

The software is in fact able to provide data for the construction of a surgical template, i.e. a template with holes that can guide the dentist in inserting the implants in the exact position without incision of the gum.

Another application of the software data could be the printing of the maxillary cast in plaster or resin useful for the dentist to have a physical model on which to set in detail the intervention that will then be performed on the patient.

The same design information through the software could be sent by the dentist to a milling machine for the creation of prostheses and accessories that can be used materially in the intervention.

From the various possibilities illustrated, it is clear how data processing through 3D software is fundamental for a fast, reliable and safe implantology intervention. However, we would like to reiterate that technology is only a valid support, the real difference lies in the hands and experience of the dentist who uses it.