After an immediate load implant surgery, although the osseointegration process has been successful, bone resorption can occur in the peri-implant areas, often due to masticatory overload.

The causes of bone resorption in the peri-implant area are mainly attributable to two conditions:

- bacterial infections;

- chewing overload.

Chewing overload: when it occurs

Chewing overload is a condition that occurs when there is inadequate distribution of mechanical stress during chewing.

The chewing load is one of the elements that is evaluated during the planning phase of the implant surgery. In fact, to avoid masticatory overload it is possible to evaluate an increase in the contact area between bone and implant, in this way it will be possible to have a more equal distribution of the chewing load.

Increase in the diameter of the dental implant

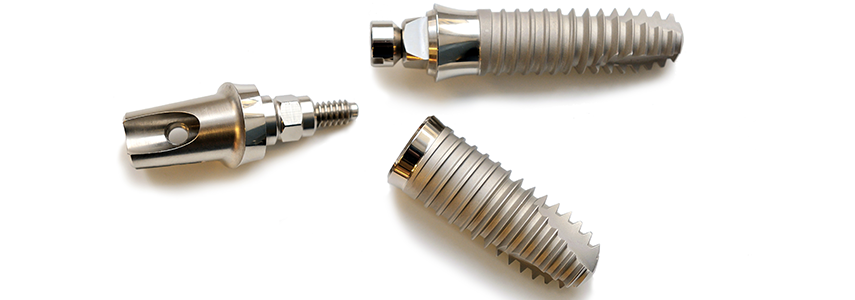

One of the options for increasing the resistance of the dental implant to chewing load is to insert dental implants with a larger diameter than standard diameter dental implants.

Among the options to pursue this goal, increasing the diameter of the implant has proven to be a successful strategy.

However, each clinical case must be evaluated individually because there may be cases in which the patient has little space on the alveolar ridge and therefore it is not possible to intervene with the insertion of implants with a larger diameter.

The excellence of a dental facility is also evaluated by the variety of dental implants available.

Having dental implants available to meet the needs of each individual clinical case is a guarantee of safety for the patient himself. Indeed, it is not the patient who must adapt to the implants, but the dental implants that must adapt to the patient.

Impact of the diameter of the dental implant on the chewing load

A group of researchers carried out an in vitro study published in the June 2020 journal Dental Materials. The research highlighted the impact of the diameter of a dental implant on the distribution of the chewing load.

The researchers recreated a three-dimensional model of a reconstructed jaw using computed tomography images of a patient’s jaw.

Subsequently, several plants were created:

- tight implants;

- normal diameter implants;

- large diameter implants.

In addition, different rehabilitation techniques were simulated:

- single dental implant;

- bridge on implants;

- entire arch with All-On-Four implant;

The chewing load was simulated on all types of implants by calculating the distribution of the mechanical stress from chewing.

Results

The data emerging from the research showed that the correct distribution of the masticatory load on the implants allows to avoid implant failure due to a masticatory overload.

A further reduction in chewing stress is achieved by increasing the diameter of the dental implant.

The planning of the implant surgery therefore remains a fundamental phase of rehabilitation.